New Technology and Product Recommendation – Opicker Series- Floating Oil Recovery System

Source of Oily Wastewater

In the industrial production process, a great deal of oily wastewater is discharged to meet the needs of production and equipment maintenance. The sources of oily wastewater are very extensive in China, mainly generated in the following four industries:

(1) Food and catering industry: In the process of food production and processing in China, oily wastewater is generated during equipment cleaning and machine lubrication.

(2) Metal smelting industry: In the process of smelting metals, it is necessary to cool, clean, and lubricate materials and equipment that come into contact with oil, and lubricating oil may also come into direct contact with them, resulting in oily wastewater.

(3) The chemical and pharmaceutical industry: In the manufacturing process, plenty of water and lubricating oil are used in stages such as raw material reaction, product separation, and raw material pretreatment, resulting in a large amount of oily wastewater in the later stage.

(4) Petrochemical industry: In China's petrochemical industry, almost every step from extraction to transportation and consumption generates oily wastewater. With the rapid development of science and technology in China, the tertiary oil recovery technology has also been widely applied, improving its oil displacement effect, but also making the composition of wastewater more complex.

The Current Situation of Oil-water Separation

Oil and water are immiscible liquids, and most of the oil floats on the water surface. According to national environmental protection and factory process requirements, it is necessary to separate oil and water. The mechanical structure used in existing oil removal devices for oil-water separation cannot repeatedly collect and process oil and water, and both oil and water are flowing liquids. When oil flows, water is easily moved along with the flow of oil, resulting in incomplete oil-water separation. In addition, existing oil removal devices cannot effectively adjust and efficiently collect floating oil based on its height for a long time. However, if oily wastewater is not effectively treated, a large amount of VOCs will evaporate. In order to alleviate the volatilization of VOCs in oily wastewater and other environmental pollution caused, we need to separate and collect these floating oils on the water surface.

Our Solutions

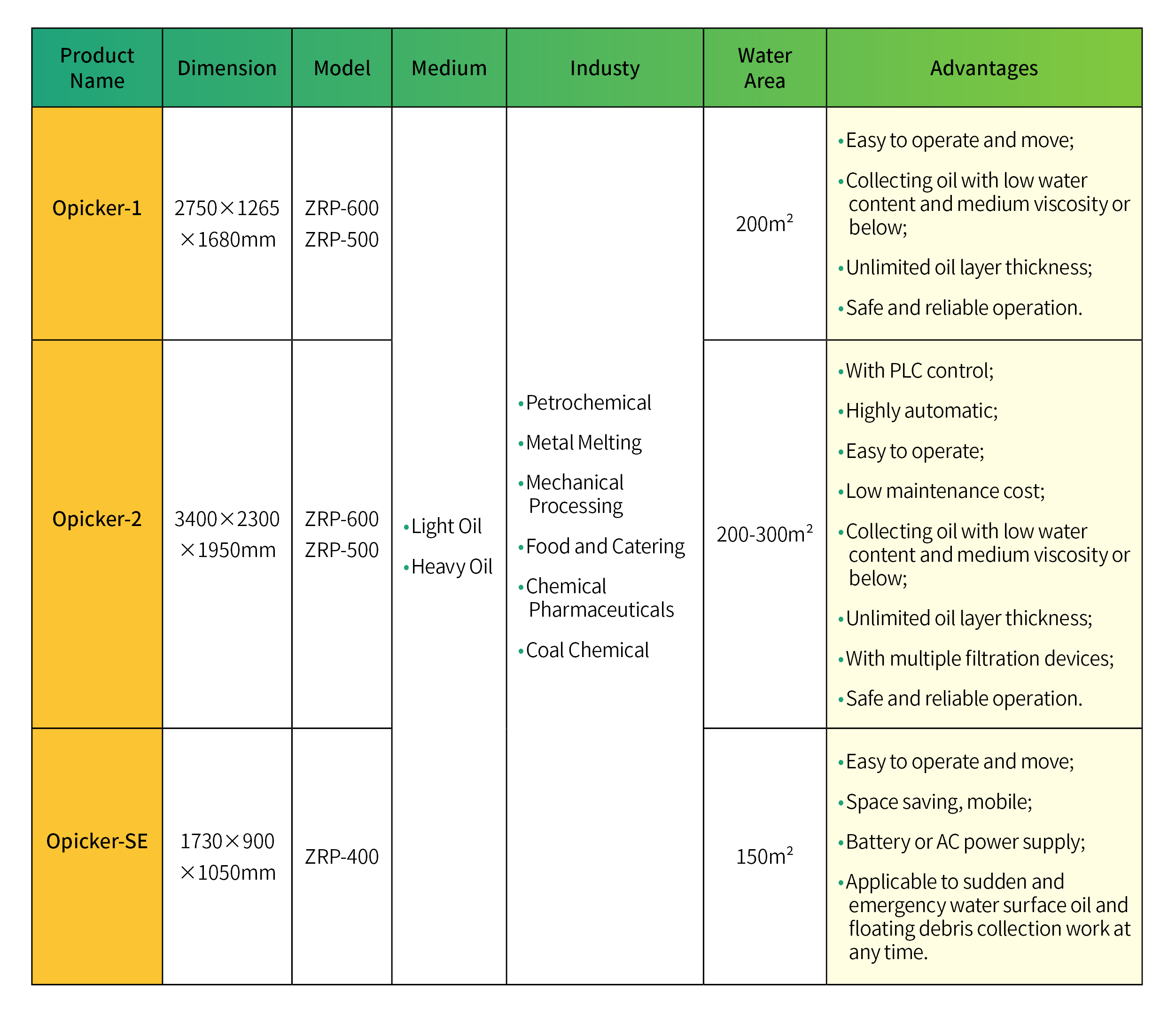

In order to improve oil collection efficiency, reduce maintenance cycles, lower maintenance costs, and achieve efficient and automated collection and recycling of floating oil and floating pollutants, we have developed three series of high-efficiency floating oil collection devices, mainly Opicker-1, Opicker-2, and Opicker-SE, which can be applied to various working conditions and meet the needs of different owners.

The following is an introduction to our products including specifications, models, and applicable scenarios:

Opicker-1

Opicker-2

Opicker-SE

Foating oil collector

Technical Advantages

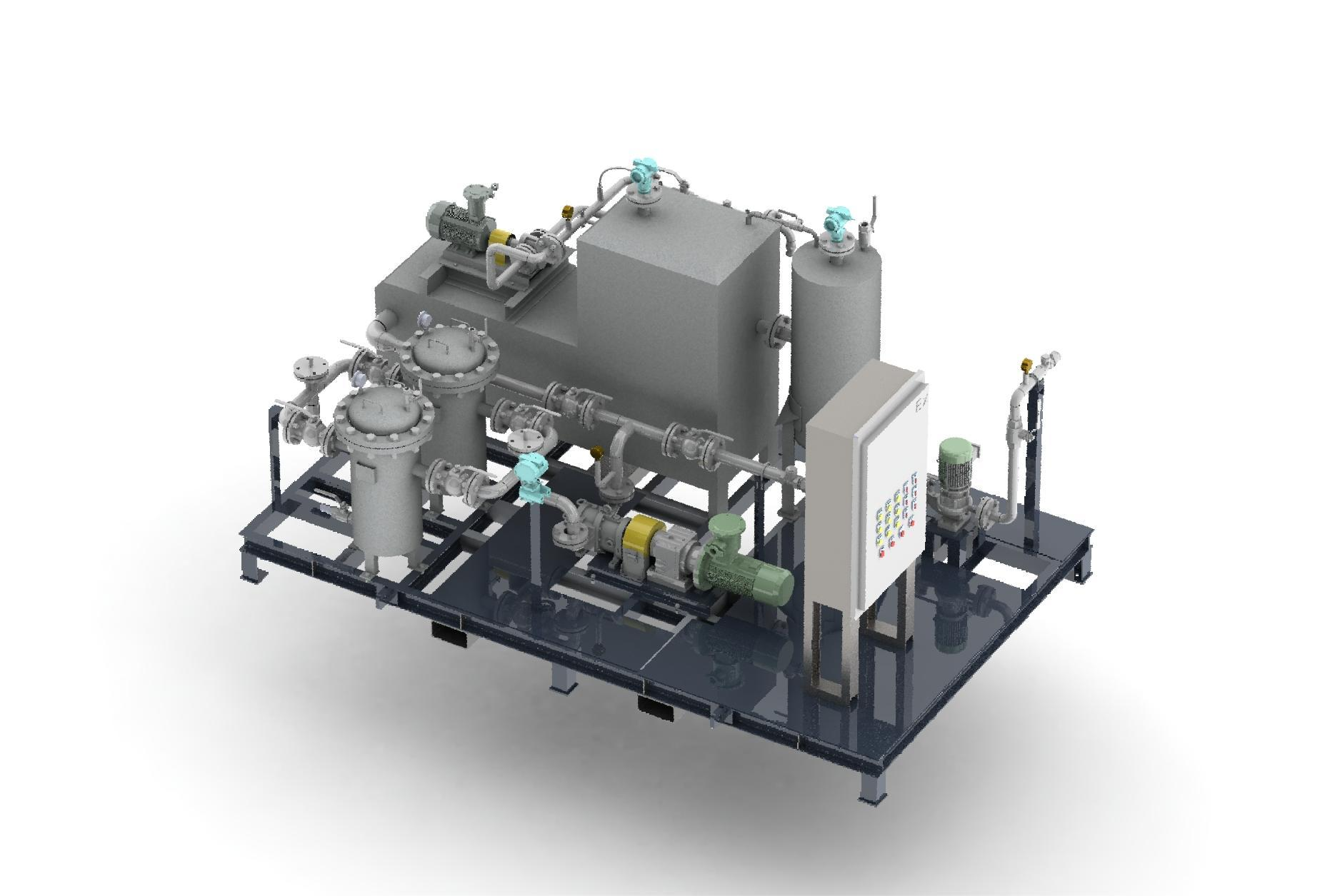

(1) Reasonable product structure design, highly automatic, easy to move and operate;

(2) With low maintenance costs and can be powered by either batteries or alternating current, resulting in low system energy consumption;

(3) The structure design of the water surface collection device is compact and does not require additional power drive. It can float naturally on the water surface for a long time without frequent maintenance;

(4)The floating oil is collected by overflow method, and the overflow layer always maintains a dynamically stable collection state of thickness, which is not affected by water surface fluctuations, and the collected oil-water mixture has a high oil content ratio;

(5)A secondary oil-water separation device has been added on the ground, resulting in low water content in the recovered oil;

(6)With fast oil collection speed and high collection efficiency;

(7)Collect oil with a wide range of viscosity, including oils with medium viscosity or below;

(8)No limit to the thickness of the oil layer;

(9) The collection device and separation device are respectively equipped with filter screens, which can prevent suspended solids from blocking and ensure safe and reliable operation of the equipment.

Applications

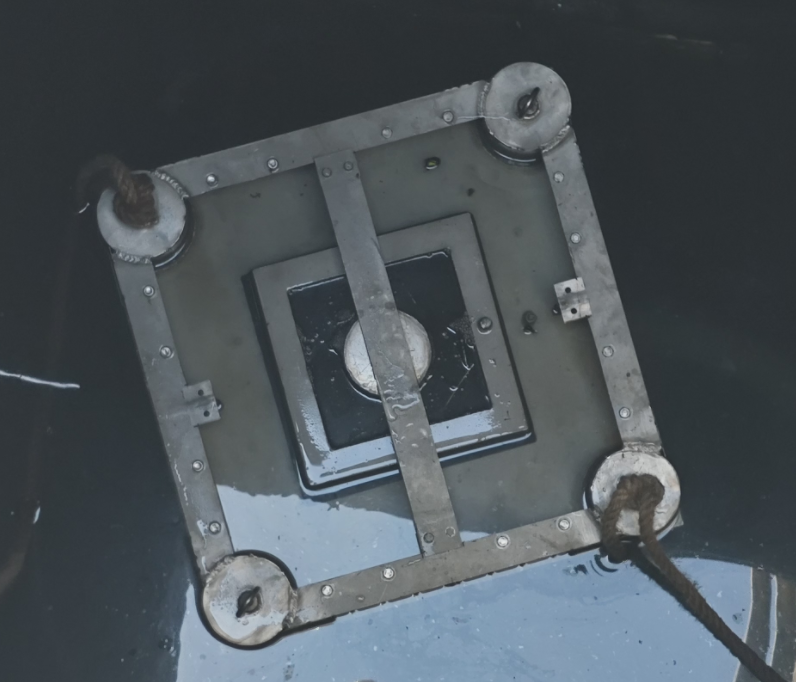

Opicker can be widely used in treatment of oily wastewater containing engine oil, diesel, lubricating oil, and vegetable oil in industries such as metallurgy, refining, and petrochemicals. (The following picture shows the collection of floating oil in the oily water tank of a petrochemical plant)

(Panoramic view of oily water tank) (Inside the oily water tank)

1. Cases

Project Name: Collection of floating oil in the oily water tank of a petrochemical plant

Introduction: The oily water tank of a petrochemical plant contains light oil and a large amount of oily flocculent substances. The thickness of the oil layer is about 10mm. It is necessary to recover and treat the oil layer on the surface of the sewage tank to reduce the volatilization of VOCs.

Site picture: Before using our equipment, the on-site oil tank is shown in the picture. There is a visible oil film on the water surface in the oil tank, and the water surface is black in color. The water surface is not transparent, and there is a serious pungent odor in the tank.

When the floating oil collector collects, the oil and stains floating on the water surface are simultaneously recovered. After the equipment runs for 2 hours, the floating oil on the water surface has been collected, and the water surface is transparent and clear, with a reduced pungent odor.

Previous

Previous