Good News: Hydrophobic Lipophilic Filter Pilot Plant of MSTN Group Successfully Operated

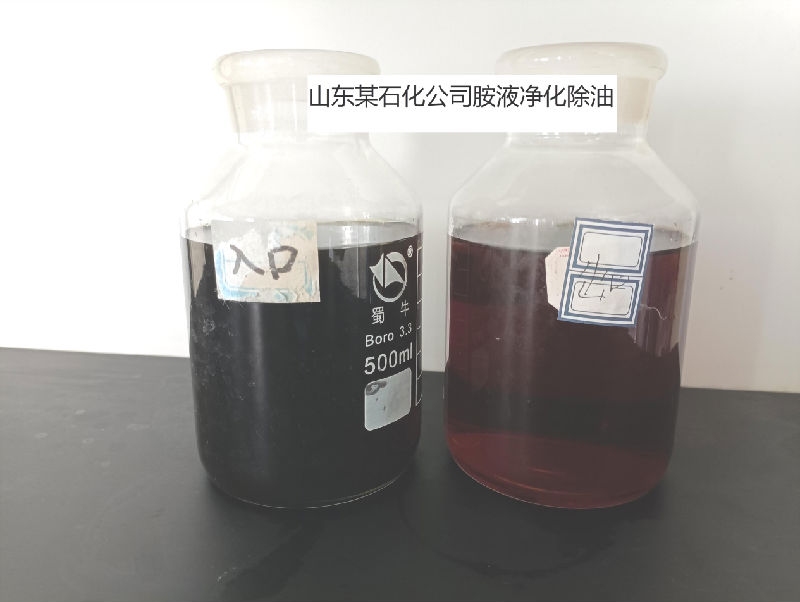

Recently, the pilot plant of graphene~based hydrophobic lipophilic filter (model: Isplitter) independently researched and developed by MSTN Group and its subsidiary SmartCmeta Marterial Technologies Ltd. has been successfully operated in the amine liquid purification and de~oiling section of a petrochemical company in Shandong Province, which has realized the efficient separation of oil and amine liquid from oil~containing depleted amine liquid without the loss of amine liquid and ensured the normal and stable operation of the amine liquid system.

This pilot project is a sideline device of the lean amine tank, the oil~containing amine liquid comes from the lean amine tank, and the amine liquid returns to the lean amine tank after de~oiling treatment, and the whole skid covers an area of about 6m2 (length×width of 3m*2m). The oil content of incoming amine liquid is in the range of 40~1700mg/L, and the oil content of outgoing amine liquid after treatment by Isplitter device is reduced to 15~25mg/L. There is zero loss of amine liquid during the whole treatment process, and the system operates smoothly, with stable indicators of outgoing liquid.

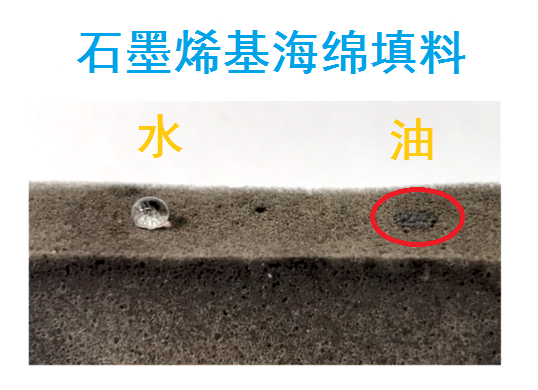

Graphene~based hydrophobic and lipophilic filter Isplitter uses graphene~modified sponge as the core component, and graphene~modified sponge has excellent lipophilic and hydrophobic properties. The principle is: the fold or edge effect on the surface of graphene reduces its surface energy, which makes the adsorption energy between the surface of graphene between the intermolecular bonding energy inside the oil droplet and the bonding energy between the water molecules inside the water droplet, and therefore shows good oleophilic performance. And the sponge and other polymer materials have special wettability after treatment by virtue of their large specific surface area and loose porous rough structure. Therefore, by utilizing the advantages of both, the superhydrophobic/super lipophilic graphene~modified sponges were obtained by modifying graphene on the surface of the internal structure of sponge~like polymers (Figure below).

The process and equipment of this pilot plant are all independently researched, developed and manufactured by MSTN Group with independent intellectual property rights of the technology and equipment, this pilot plant is the first application of graphene~based oil~water separation equipment in the amine liquid purification system, and start up and operation successful in one time, which verifies and affirms that the MSTN Group has been dedicated to the research and development of graphene in different application scenarios of the exploration of the road and its R & D strength, and to promote the application of graphene in the environmental protection industry is of great practical significance.

Previous

Previous