New Technology and Product Recommendation—Eddyflo- Efficient Three-Phase Liquid Separation Technology and Its Application

About Eddyflo- Efficient Three-Phase Liquid Separation Technology

The existence status of oil pollutants in water can be roughly divided into floating oil, dispersed oil, emulsified oil, and dissolved oil. After oil pollutants enter the water, they will form oil films of varying thicknesses on the surface of the water. The oil films will cause a sharp decrease in dissolved oxygen content in the water, affecting the self purification effect of the water, causing a large number of aquatic organisms to die, and damaging the aquatic ecosystem. Oil pollutants can also enter groundwater systems, affecting residential water use and agricultural irrigation. In addition, floating oil can also extract chlorinated hydrocarbons and polychlorinated biphenyls dispersed in water, directly poisoning aquatic organisms. It can be seen that the harm of petroleum pollutants to the environment cannot be ignored, and the control of petroleum pollution is an urgent problem that needs to be solved in today's society. At present, the commonly used technologies for treating oily wastewater include physical methods (sedimentation, filtration, fine filtration, etc.), chemical methods, physicochemical methods (air flotation, adsorption, etc.), and biological methods. Traditional technologies and equipment have disadvantages such as low oil removal efficiency, large land occupation, and high energy consumption during system operation.

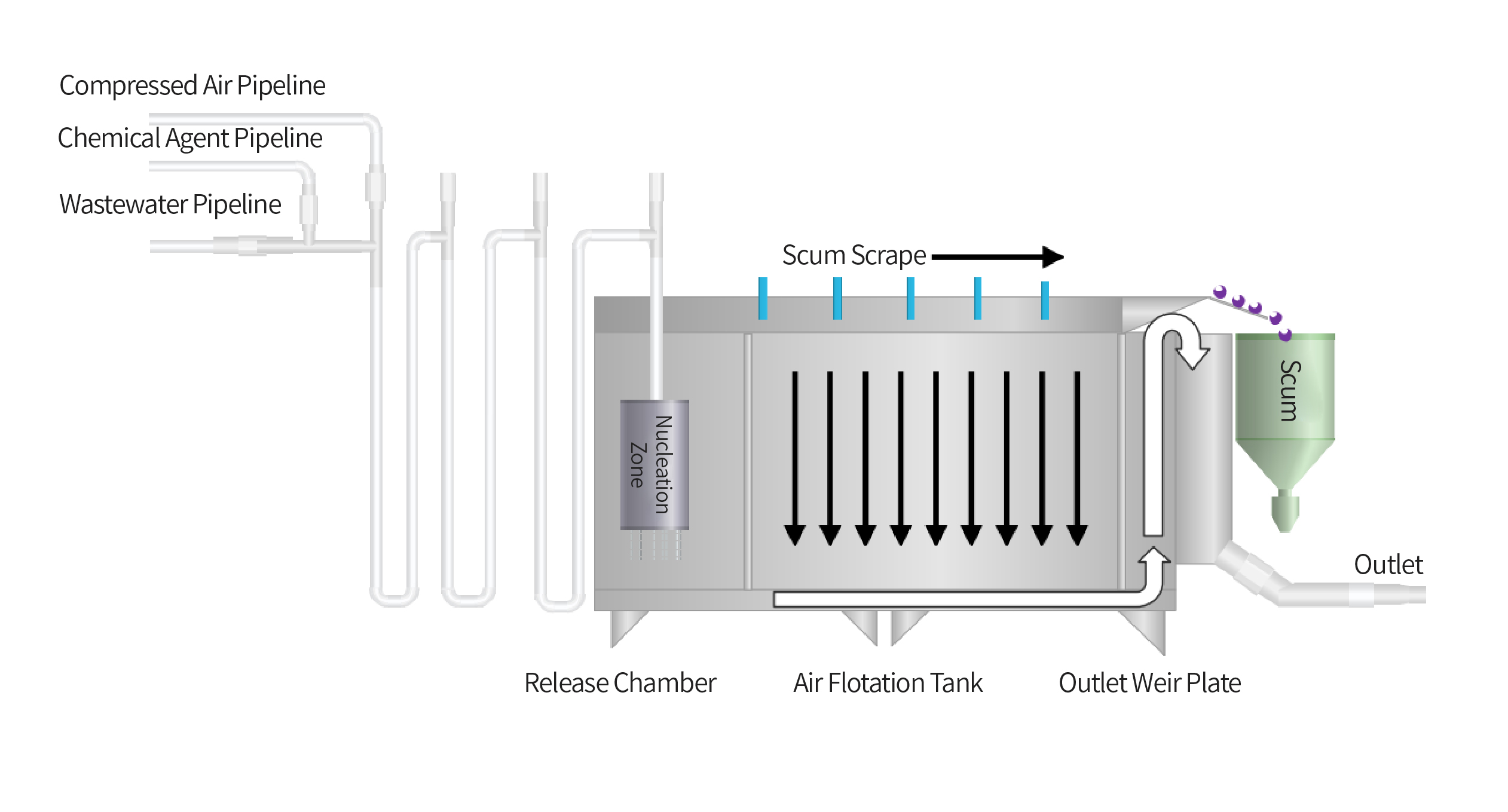

To desolve the drawbacks of traditional technology and equipment, MSTN has developed and launched the M·Eddyflo Efficient Three-Phase Liquid Separator by studying the migration and motion laws of bubbles and oil droplets in a rotating turbulent flow field. The Efficient Three-Phase Liquid Separation Technology belongs to a type of pressurized dissolved air flotation technology, which innovatively integrates high-pressure air dissolution, drug molecule stretching and efficiency improvement, coagulation and flocculation stirring (pollutant capture), floc formation, bubble nucleation generation, and ultra light hollow floc shape into a microbubble dissolved air reactor. Compared with current treatment technologies, it has achieved a combination of replacing inclined plates, eddy current pressurized gas dissolution, polymer flocculation adsorption, and air flotation, resulting in a more than 2-fold increase in overall indicators of land occupation and treatment capacity, a 40% reduction in chemical consumption, and a reduction of over 80% in the cost of recovering contaminated oil and treating one ton of water.

There are currently 2 authorized patents for this technology, one of which is "A High Energy Efficiency Air Floatation Wastewater Treatment System", utility model patent, patent number 202220023702.1; The other one is " A Mixer and Waste Liquid Treatment Equipment", invention patent, patent number 202111637947. X; This technology is also awarded "the 2023 Beijing Enterprise Evaluation Association Science and Technology Innovation Award", certificate number: BEEA-2024-026, which is an independent intellectual property of MSTN TECHNOLOGIES CO., LTD.

Technical Advantages

For oily wastewater, the Eddyflo- Efficient Three-Phase Liquid Separation Technology is effectively removing FOG and TSS, with the following characteristics:

(1) The pollutant treatment load is high, with a maximum treatment load of 22.25g crude oil/h;

(2) Small in size and occupying a small area;

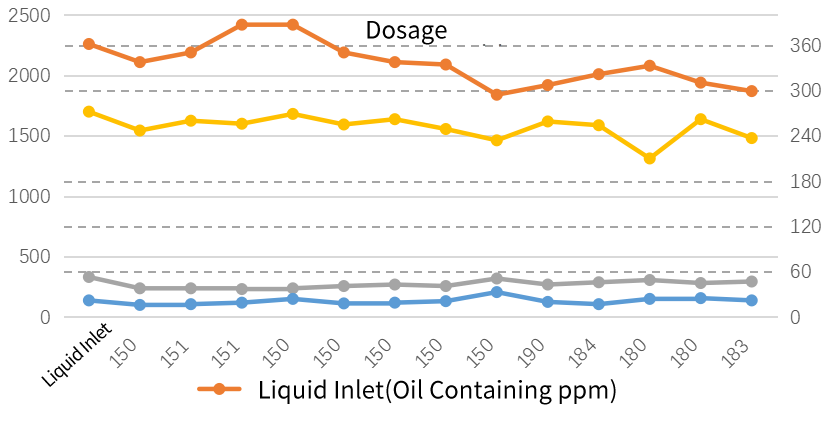

(3) The utilization rate of the added chemicals is high, and the dosage of the chemicals can meet the effluent requirements at 50ppm;

(4) Easy commissioning and expansion, non fixed facilities, and easy to move at any time.

Low Chemicals Dosage

The microbubble aerator can effectively extend the molecular chains of chemical agents, fully utilizing the charges originally coiled in the drug molecules, and increasing the pollutant capture capacity of the drug by tens of times. In addition, the Efficient Three-Phase Liquid Separation system provides complete and sufficient drug mixing function with the help of swirling flow, and the efficiency of pollutants being captured by chemical drug molecular chains is extremely high. This technical feature ensures that drugs are used to their fullest potential, achieving minimal chemicals consumption.

Strong Resistance to Impact Loads

M·Eddyflo Efficient Three-Phase Liquid Separator has a unique swirl energy regulation function, ensuring that the oil removal system can adapt to different inlet conditions. When there are sudden changes in sewage properties, temperature, and flow rate, it can quickly adapt and adjust the working conditions in a timely manner, ensuring stable water output. This technological feature breaks through the shortcomings of traditional chemical treatment processes that cannot adapt to significant changes in water quality, ensuring the stability of the entire sewage treatment process. The design of a comprehensive dosing system allows for precise dosing of chemicals based on the incoming water quality, ensuring that the system always maintains optimal treatment efficiency.

Small Area Occupation

The design of the Eddyflo- Efficient Three-Phase Liquid Separation System for sewage fully dissolved gas realizes the mixing of gas, liquid, and solid phases. The perfect pressure regulation system can generate bubbles in the nucleation state, achieve a minimum bubble diameter close to zero, and directly grow inside the floc particles without the need for attachment process. This technological feature realizes the innovation of floc floating, eliminating the preparation of dissolved water, circulating water system, and slow and inefficient bubble attachment process, achieving unprecedented efficiency in removing scum and ultra small equipment volume, saving 80% of area and a large amount of infrastructure investment.

Solid Waste Reduction

Due to the full contact between chemicals and pollutants, not only does it reduce the consumption of chemicals, but it also greatly increases the density of flocs and reduces the moisture content of sludge. The continuous release of bubbles allows the sludge to continuously dehydrate, and the solid content of the sludge is close to 10%. Due to the complete destruction of the elastic system of the emulsion, pollutants are tightly wrapped and entangled by the long chains of polymer agents, resulting in an extremely clear mud water interface. The sludge can be easily dehydrated without the need for conditioning.

Case Sharing

Case 1: A 5000m3/d production water vortex three-phase treatment project for a certain offshore platform

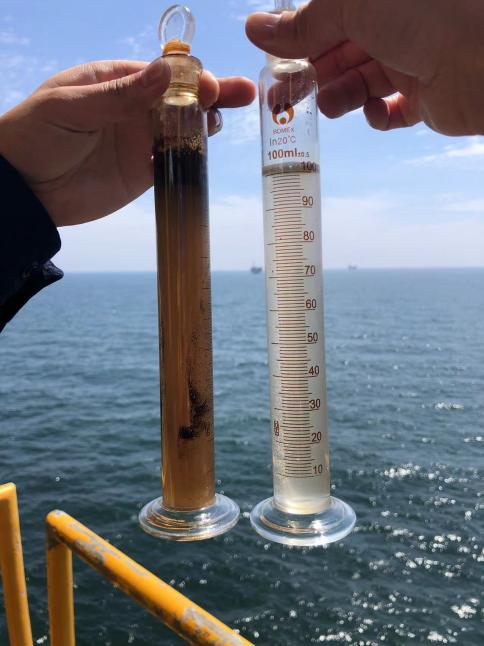

MSTN treated its 5000m3/d oilfield production water on an offshore platform, with an oil content of 1000-5000mg/L and TSS content of 300-400mg/L before treatment. After treatment, the oil content was less than 50mg/L and the TSS content was less than 40mg/L. The equipment is divided into air flotation skid, slag removal skid, dosing skid, pump skid, etc., with a total comprehensive area of 75m2 and a core equipment area of 12m2.