New Technology and Product Recommendation——Graphene Oleophilic Hydrophobic Filter

About Graphene Oleophilic Hydrophobic Filter and Its Application

Graphene oleophilic hydrophobic filter is a continuous flow extrusion regeneration oil-water separator developed by SmartCmeta Marterial Technology Co., Ltd., a wholly-owned subsidiary of MSTN TECHNOLOGIES CO., LTD., based on its independently developed graphene modified material with hydrophilic and hydrophobic functions, which can achieve oil-water separation. This filter can be applied in various scenarios such as oilfield produced water, coking wastewater, oily amine solution, machining wastewater, slaughterhouse wastewater, etc. for waste oil separation and recovery.

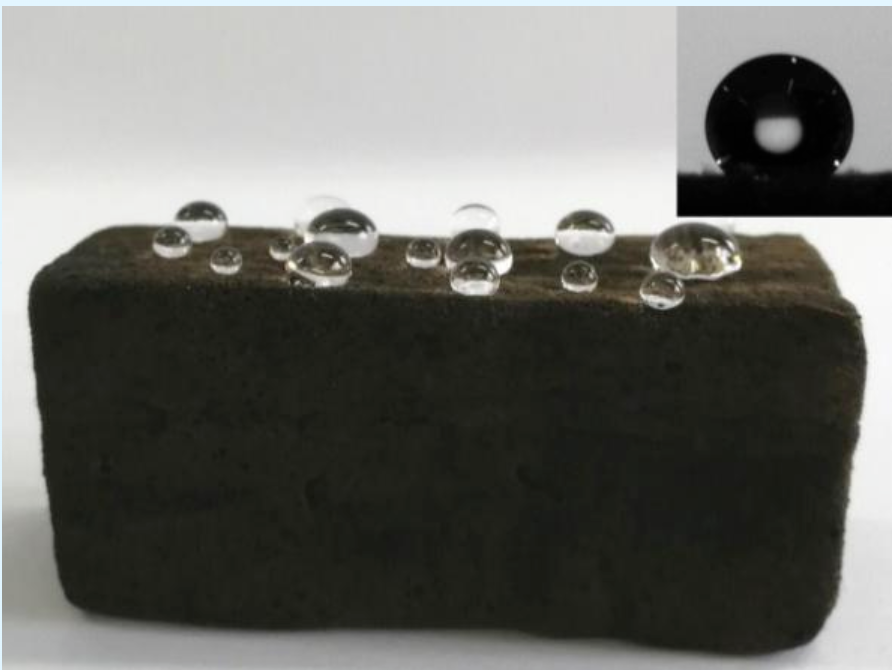

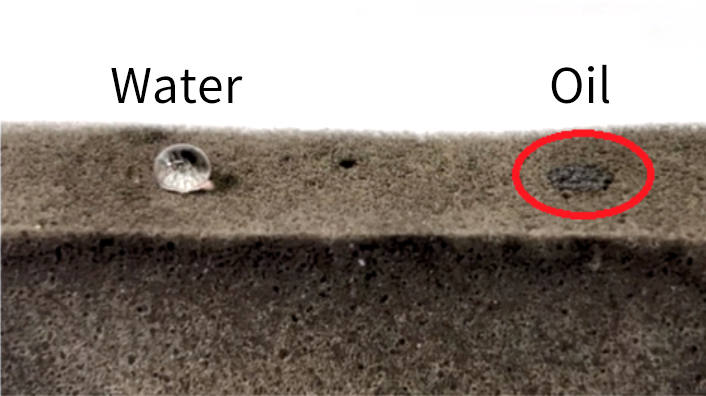

Sponge, absorbent felt, fiber cotton and other porous flexible materials have excellent adsorption performance due to their microporous structure. We use a sponge with appropriate porosity, density, and excellent mechanical properties as the substrate, and modify the sponge with graphene material. By utilizing the lipophilic and hydrophobic properties of graphene, the modified graphene based sponge retains the excellent adsorption performance of the sponge while possessing the lipophilic and hydrophobic properties of graphene material. When encountering oil-water mixtures, the modified graphene based oil absorbing sponge can achieve only oil absorption but not water absorption. Water droplets form spherical shapes on the surface of graphene sponge, rolling back and forth like on the surface of lotus leaves.

The contact angle of water can reach over 150 °, while the contact angle of oil is 0 °.

Our Graphene modified materials and technology equipment have been granted 3 patents, 1 software copyright, and 1 appearance patent, with fully independent intellectual property rights, and have been rated as a new technology and product in Beijing.

Progressiveness

The Graphene oleophilic hydrophobic filter adopts the characteristics of graphene nanomaterials, which are lipophilic and hydrophobic. It effectively separates wastewater containing oil or organic solvents, amine liquids, etc. The device is simple and efficient, and can meet various needs of liquid discharge treatment in petroleum and petrochemical plants; And the recovered oil or organic solvents have high quality and can also be recycled as resources, which not only reduces treatment costs but also brings value-added benefits from resource utilization.

The following are the characteristics of Graphene Oleophilic Hydrophobic Filter:

1) Oil water separation performance up to 99.9%

Graphene modified materials have efficient oleophilic and hydrophobic properties, combined with unique equipment structure, residence time and other designs, resulting in a high oil removal and recovery rate of 99.9% in the device.

2) Squeezing regeneration andlow energy consumption

Graphene modified materials are flexible materials that, after oil absorption and saturation, discharge dirty oil or organic solvents through extrusion, without the need for backwashing, secondary wastewater generation, or backwashing expansion.

(3) The absorbed oil has high purity and good quality, which can achieve resource utilization

The oil discharged through compression regeneration has a low water content and impurity content, and can be recycled as fuel or other resources;

(4) Single unit continuous operation cycle adjustable

Adjust the continuous operation cycle of the equipment in a timely manner based on the oil content of the inlet liquid, the requirements for the outlet water, the equipment residence time, and on-site operation requirements;

(5) Modular and easy to assemble

If the discharge load of the upstream device increases, the processing capacity of the system can be improved by adding modules;

(6) Atmospheric pressure equipment with low energy consumption;

The device has a low requirement for the incoming liquid pressure, with an inlet pressure below 0.05MPa, and there is no need to configure an inlet pump with a higher head;

(7) The equipment has a simple structure, low failure rate, and is easy to clean and maintain.

(8) Graphene modified materials

The oil absorbing material has a high oil absorption capacity and can last up to 2 years without replacement.

Good acid and alkali resistance, with a temperature resistance of up to 200 ℃, and can be reused.

(9)Suitable for various oil products and organic solvents, such as crude oil, gasoline, kerosene, diesel, edible oil, etc.

(10) No need additional chemical agents

(11) High degree of automation

There is an online oil discharge analyzer, which automatically controls the start and stop of filters between different filters through oil discharge or time signals, and automatically switches between filters.

(12) Skid-mounted Type

Integrating filters, pipelines, shut-off valves, PLCs, etc. into one skidwith a small area occipation and on-site workload.

Case Sharing

Case 1: Amine liquid oil removal side line test of a dry gas desulfurization system of one petrochemical company.

The on-site pilot plant of Graphene Oleophilic Hydrophobic Filter is used to remove oil from the amine liquid in front of the lean liquid tank of organic amine absorbent for dry gas desulfurization in a certain refinery. This achieves efficient separation of oil and amine liquid from the oily amine liquid, ensuring the normal and stable operation of the amine liquid absorption system for dry gas desulfurization.

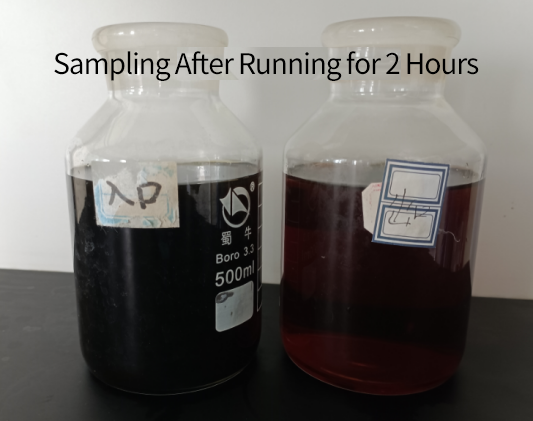

After the device is started, it runs continuously for more than 1200 hours, and the initial oil content of the amine liquid in the inlet fluctuates between 50-1700 mg/L. After passing through the graphene modified material device, the oil content of the amine liquid in the outlet drops to 13-25mg/L. The amine liquid has zero loss throughout the entire treatment process, and the system runs smoothly with stable output indicators.

The Graphene Oleophilic Hydrophobic Filter uses graphene modified sponge as the core component, which has excellent oleophilic and hydrophobic properties. This process and equipment are patented technology equipment independently developed and manufactured by our company with independent intellectual property rights.

The official launch of the on-site pilot plant is the first application of graphene based oil-water separation equipment in amine purification systems, which has important practical significance for promoting the application of graphene in the environmental protection industry.

Case 2: Oil removal test of a coking electric desalination wastewater of one petrochemical company.

After treatment with a graphene modified material device, the residence time is 25 minutes. The oil content in the raw water is 821.32mg/L, and the oil has a high bubbly viscosity; The oil content of the treated effluent is 26.57mg/L.

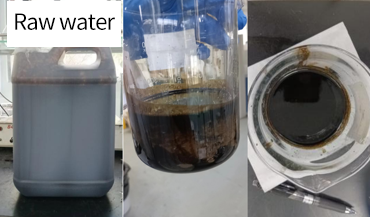

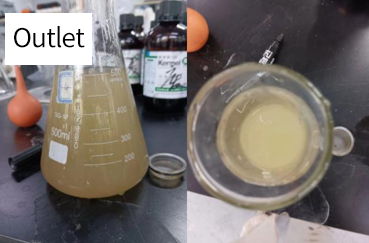

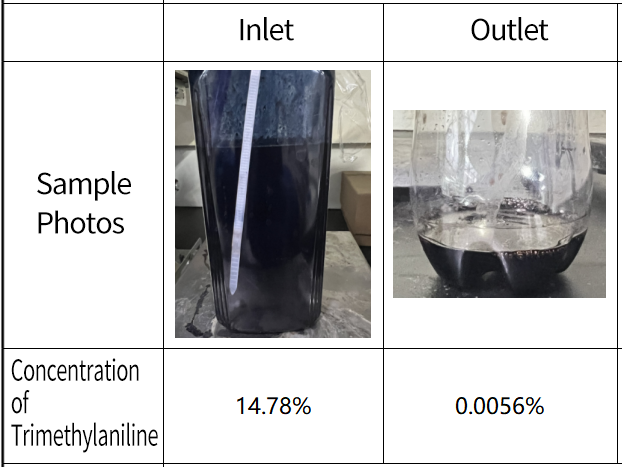

Case 3: Recovery of Trimethylaniline

The wastewater discharged from the production process of a certain factory contains a large amount of trimethylaniline. In order to reduce the loss of this component, graphene modified materials and devices were used for recovery and treatment, with a recovery rate of over 99.9%.

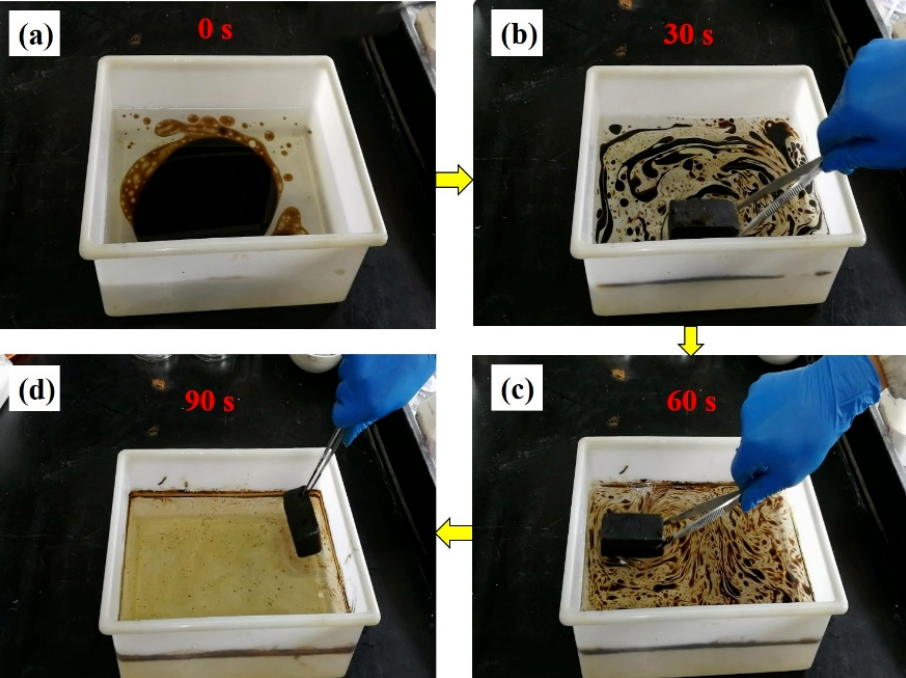

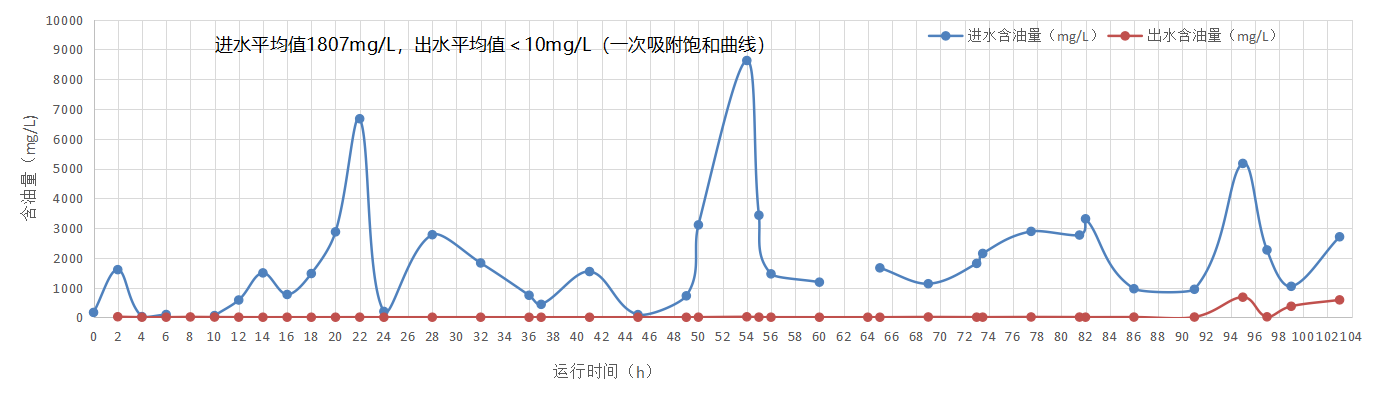

Case 4: Wastewater treatment of sewage tank of one petrochemical company

The sewage tank discharge of a certain petrochemical company was treated, and the above figure shows the continuous operation of the filter for one week before compression regeneration. The oil content in the inlet fluctuated greatly, with an average value of 1807mg/L; Before the sudden change in oil content in the effluent, the oil content in the effluent remained stable below 10mg/L.

Previous

Previous