Business Field

-

Technologies

-

Process Technologies

-

Flue Gas Treatment

-

DeSOx Technology

- Wet DeSOx and Dust Collection Technology

- M·Dwave® reverse jetting technology

- M·Sulfurp® acid gas treatment/waste acid recovery technology

- M·Sorb® sulfur dioxide recovery technology

- M·HyPerO®Hydrogen Peroxide Oxidation DeSOx Technology

- M·SWFGD seawater desulfurization technology

- M·SemiD® semi-dry desulfurization technology

- DeNOx Technology

- Decarbonization Technology

- Colored Plume Elimination Technology

- VOCs Treatment Technology

- H2S Removal Technology

-

DeSOx Technology

- Waste Water Treatment

-

Flue Gas Treatment

- Internet of Things

-

Process Technologies

- Materials

- Products

- Services

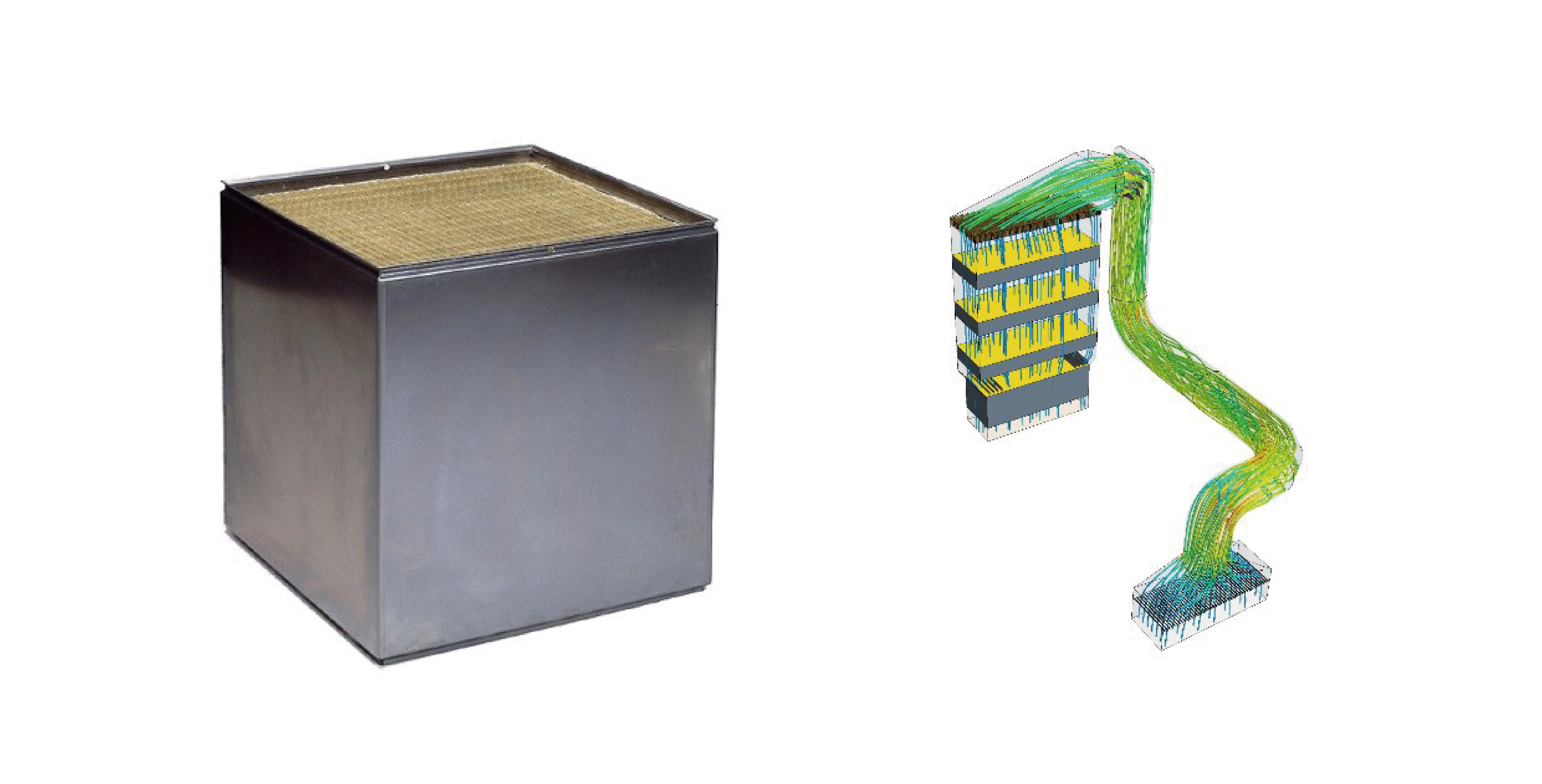

M·SCR DeNOx technology

This process uses NH℃ as a reductant to convert NOx into N2 and H2O under the action of catalyst.

Technical Advantages

- The DeNOx catalyst it uses has a wide reaction temperature window from 150 to 550;

- Flow field simulation makes the overall design optimized;

- It produces no secondary pollutants;

- It has a high DeNOx efficiency, meeting the cleaning emission standard;

- It is easy to reconstruct and requires a small quantity of works.

Case

1,000,000 t/a Ethylene Cracking Furnace (6 sets) of a Company

| Para. | Raw gas | Design index |

|---|---|---|

| Flue gas flow rate, Nm³/h | 175000wet basis | |

| NOx mg/Nm³ | 100 wet basis | 35 dry basis |