Business Field

-

Technologies

-

Process Technologies

-

Flue Gas Treatment

-

DeSOx Technology

- Wet DeSOx and Dust Collection Technology

- M·Dwave® reverse jetting technology

- M·Sulfurp® acid gas treatment/waste acid recovery technology

- M·Sorb® sulfur dioxide recovery technology

- M·HyPerO®Hydrogen Peroxide Oxidation DeSOx Technology

- M·SWFGD seawater desulfurization technology

- M·SemiD® semi-dry desulfurization technology

- DeNOx Technology

- Decarbonization Technology

- Colored Plume Elimination Technology

- VOCs Treatment Technology

- H2S Removal Technology

-

DeSOx Technology

- Waste Water Treatment

-

Flue Gas Treatment

- Internet of Things

-

Process Technologies

- Materials

- Products

- Services

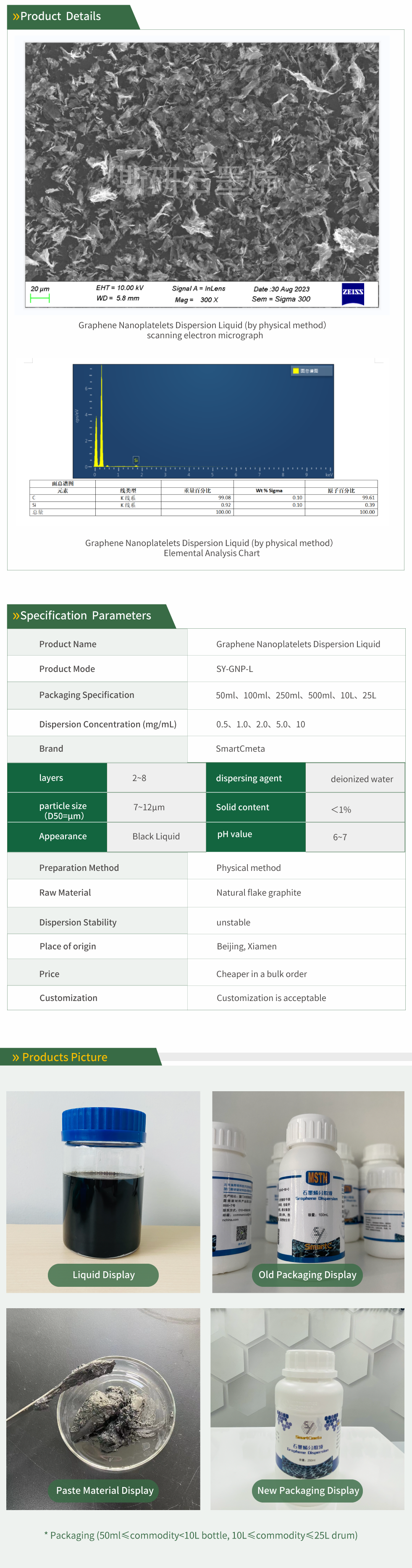

Graphene Nanoplatelets Dispersion Liquid

This product is made of natural flake graphite as raw material to get graphene products through physical exfoliation process. It has the advantages of high purity, large specific surface area, high stability, etc. The graphene microfilm exfoliated by physical method does not have the oxidation process of strong oxidizing agent, does not introduce lattice defects, and has excellent electrical con- ductivity. The most commonly used dispersant is water, while ethanol, ethyl, NMP, DMF, etc. can also be used as a dispersant. Graphene dispersion is not stable, so an appropriate amount of dispersing additives are required.

Technical Advantages

- High product quality: no introduction of lattice defects;

- Less impurity content: all-round control of metal impurity content, to meet customer demand for high purity; Good electrical conductivity: physical method of preparing graphene powder with few defects, excellent electrical and thermal conductivity;

- No dust pollution in liquid form, easy to add, and it is convenient for operation;

- Good stability of the dispersed liquid, less agglomeration, and the product maintains a monolayer dispersion state.