Business Field

-

Technologies

-

Process Technologies

-

Flue Gas Treatment

-

DeSOx Technology

- Wet DeSOx and Dust Collection Technology

- M·Dwave® reverse jetting technology

- M·Sulfurp® acid gas treatment/waste acid recovery technology

- M·Sorb® sulfur dioxide recovery technology

- M·HyPerO®Hydrogen Peroxide Oxidation DeSOx Technology

- M·SWFGD seawater desulfurization technology

- M·SemiD® semi-dry desulfurization technology

- DeNOx Technology

- Decarbonization Technology

- Colored Plume Elimination Technology

- VOCs Treatment Technology

- H2S Removal Technology

-

DeSOx Technology

- Waste Water Treatment

-

Flue Gas Treatment

- Internet of Things

-

Process Technologies

- Materials

- Products

- Services

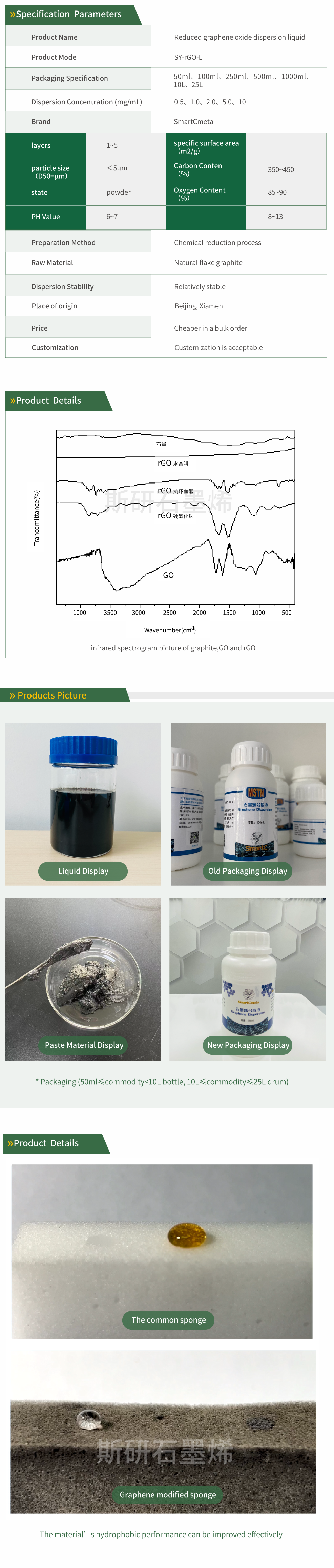

Reduced Graphene Oxide Dispersion Liquid

Graphene material produced starting from GO with chemical reduction or thermal reduction process will be called reduced graphene oxide(rGO). In some applications, GO to rGO's reduction is done during the material composite process.First, using GO's good surface wettability for dispersion, then in-situ reduction is carried out to achieve the composite of different materials. RGO's surface defect site is relatively lesser than GO and it is more closer to single-layer graphene in structure and property.The most commonly used dispersant is deionized water, while ethanol,NMP, DMF, etc., can also be used as a dispersant for rGO.

Technical Advantages

- Thin layer, stable dispersion, easy for processing;

- Better lubrication effect, lower layer, with better wear resistance, is a good composite material;

- rGO dispersion liquid(with chemical reduction process) still keep a little oxygen-containing functional groups,the properties are more active then GNP(graphene produced by physical method), will be more easier to graft mod- ification then composite with other materials. rGO products can be customized according to different reduction methods and reducing agents.