Business Field

-

Technologies

-

Process Technologies

-

Flue Gas Treatment

-

DeSOx Technology

- Wet DeSOx and Dust Collection Technology

- M·Dwave® reverse jetting technology

- M·Sulfurp® acid gas treatment/waste acid recovery technology

- M·Sorb® sulfur dioxide recovery technology

- M·HyPerO®Hydrogen Peroxide Oxidation DeSOx Technology

- M·SWFGD seawater desulfurization technology

- M·SemiD® semi-dry desulfurization technology

- DeNOx Technology

- Decarbonization Technology

- Colored Plume Elimination Technology

- VOCs Treatment Technology

- H2S Removal Technology

-

DeSOx Technology

- Waste Water Treatment

-

Flue Gas Treatment

- Internet of Things

-

Process Technologies

- Materials

- Products

- Services

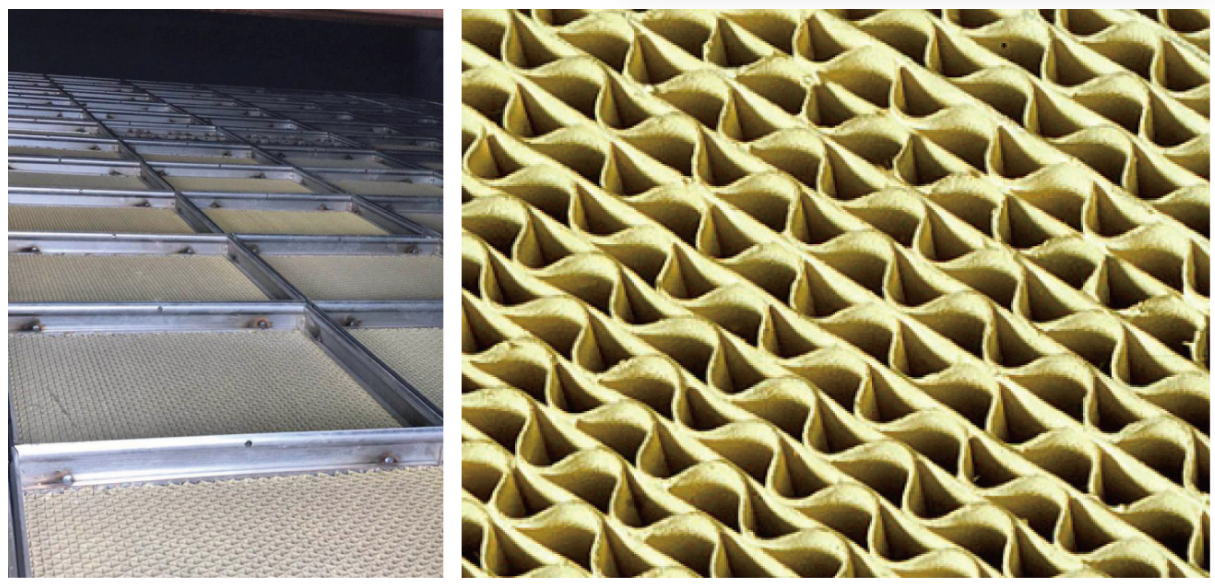

SCR catalyst

It has a unique corrugated plate structure and undergoes two impregnation and two baking processes to ensure the uniformity of the active substance. In addition, it has "large, medium and small sized" micropores, greatly improving its specific surface area.

Technical Advantages

- Its specific surface area is twice that of the traditional honeycomb catalyst;

- It has a superior poison tolerance, doubling the chemical lifetime;

- Its weight per unit (by volume) is about 50% of the traditional honeycomb catalyst;

- It is produced domestically, making the lead time guaranteed.